Tapping acrylic is fairly easy as long as you use the correct tap. Screwing and Tapping perspex® or Acrylic

Standard taps and dies may be used for cutting screw threads in Perspex® but wherever possible, coarse threads are preferred as they are less liable to damage. Lubricants are essential, water or soluble oil being preferred.

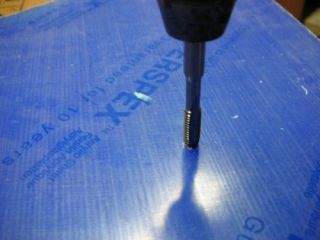

In order to tap acrylic you need to drill the correct sized clearance hole, just like you would in metal. Ensure that the hole is drilled squarely.

Push the tap into the hole and turn it slowly clockwise. Use some water or suluble oil to lubricate the tap. Turn the tap a few times clockwise and then turn it anti-clockwise. Then complete a few more clockwise turns until you have sucessfully threaded the perspex®

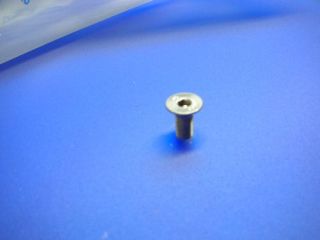

You can now remove the tap and screw in the correct size machine screw. Threads must not be overstressed and it is not advisable to thread Perspex® if frequent dismantling is likely. In such conditions, threaded metal inserts are recommended.