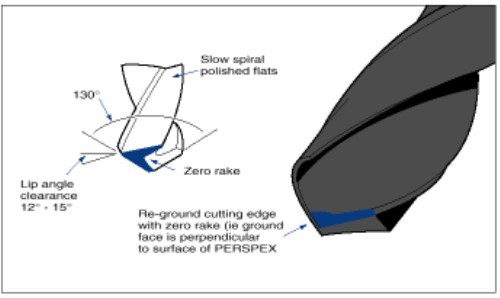

Acrylic such as Perspex or Plexiglas can easily be drilled and machined with the correct tools. When drilling acrylic a drill bit with a negative rake works well, for this reason a cobalt drill often works well as the cut angle is is better suited to drilling acrylic. In most cases acrylic can be drilled with no lubricant, although water can be used if needed.

Standard drill (130°) with cutting edges re-ground for use with Perspex®

When drilling acrylic a slow speed is recommended, if you use a high speed there is a chance that too much heat will be produced via friction and this can cause the acrylic to melt or be damaged by the heat. A back stop should also be used to prevent break out, this can be made from a scrap piece of acrylic or a hard piece of wood. Coolants are recommended when drilling deep holes into acrylic.

Never use a centre punch on acrylic as it will break. If you need to get a larger diameter drill started you can use a smaller drill to use a pilot hole or you can use a centre drill.

Hole saws can be used on acrylic, but pay particular attention to the drill in the arbour as this can break the acrylic when exiting the work piece.

Using a bench drill is a good way to drill perspex, this way you can ensure that the hole is perfectly straight.

Be sure to stop the drill occasionally to remove the build up of swarf.

Acrylic can be turned, engraved and machined with a router as long as the correct speed is chosen. Coolants are recommended when Turning.